Bird's-Eye View

Developing the products is one thing, and applying the products to the field sites requires knowledge of associated products and some level of understanding of the code of conduct. As an LED Lighting Solution provider, we emphasize field application participation because talking to our customers is always fun. We can usually obtain new development ideas from the communications. In the past few years, through various project experiences and contact with different types of customers, we have better understood our product strengths and how to improve products. We're thrilled that all the products developed have successfully installed and serve our customers. At the same time, we found many customers were relatively unfamiliar with LED control products during our customer communications. Thus, we'd like to provide an overview of dimming and dynamic lighting solutions for a high-level understanding. See our Product Solutions brochure.

Phase-cut Dimmers

These are commonly known as "dimmer switches" in the market. Phase-cut dimming is a generic term that describes the dimming operations by controlling the input power from the Live wire to the lights. Based on the different phase-cut methodologies, we can further divide phase-cut dimming into leading-edge and trailing-edge phase-cut dimming.

These are commonly known as "dimmer switches" in the market. Phase-cut dimming is a generic term that describes the dimming operations by controlling the input power from the Live wire to the lights. Based on the different phase-cut methodologies, we can further divide phase-cut dimming into leading-edge and trailing-edge phase-cut dimming.

The traditional light dimmers (Incandescent or TRIAC dimmers) consist of a TRIAC IC and several passive components and belong to the leading-edge phase-dimming and are suitable for resistive loads, such as tungsten and quartz lamps. However, the traditional dimmers are not eligible for capacitive loads such as LEDs. When people use Incandescent dimmers with LED dimming, common issues include flickering at the low level and a much shorter dimmer product lifespan. Furthermore, even with the same product SKUs, inconsistency in the dimming performance becomes a project nightmare.

For LED lamps capable of working in shallow power consumption environments, our digital trailing-edge output phase dimmers do not require a neutral wire. Thus, Electricians can connect the dimmer in series with a regular light switch (in a Live wire-in and Live wire-out manner), same as the Incandescent dimmer. This critical feature makes our digital LED dimmers feasible as a direct replacement for traditional dimmers and works with LED lights. Additionally, Electricians can utilize the minimum brightness memory function for setting the dimming range, another feature required in LED dimming.

To assist customers and prospects in better understanding the fundamental difference between the two types of dimmers and why we claim the trailing-edge dimmers are better in LED dimming, we created an exciting video using some market-available dimmers a while ago. Although it started nicely with the incandescent dimmers with some dimmable LED fixtures, we found in the second part of the video that the same set of leading-edge dimmers failed and showed severe flickering with other dimmable LED lights. Interested prospects can learn more about our findings.

1-10V Controllers

1-10V and 0-10V, which are often confused in the market, both refer to controlling the output of the LED driver linearly to dim the light. The most significant difference is how the LED driver changes its output with an input below 1V.

1-10V and 0-10V, which are often confused in the market, both refer to controlling the output of the LED driver linearly to dim the light. The most significant difference is how the LED driver changes its output with an input below 1V.

Since there is no unified standard for 0-1V in the market, the response of different brands of LED 0/1-10V dimmable drivers can also be very different. In other words, we can understand 1V as the critical point, above which is linear dimming, and below which is no longer linear dimming.

When judging which products would be needed, we suggest customers consider the followings. Wiring: 1-10V requires a two-wire connection (DIM+/-), and 0-10V requires a four-wire connection (DIM+/-, L/N ). The implication of zero light output: We should not be confused with no light output from a LED driver as actually switching it off, just like setting the driver in sleep mode, same as switching off the TV with remote control.

Dynamic Lighting Solutions

Dynamic lighting, sometimes known as Circadian Lighting or Tunable White Lighting, typically requires unique controls and specific LED drivers with three or four-wire outputs (Cool White+/-, Warm White+/-) lights. Inside these lights, two strings of LED lamps with different color temperatures are responsible for generating the color mixing effects.

Dynamic lighting, sometimes known as Circadian Lighting or Tunable White Lighting, typically requires unique controls and specific LED drivers with three or four-wire outputs (Cool White+/-, Warm White+/-) lights. Inside these lights, two strings of LED lamps with different color temperatures are responsible for generating the color mixing effects.

Our proprietary Dynamic Lighting solution separates the control of brightness and color temperature. Thus, the solution uses single-channel dimmable LED drivers (LED+/-) to power Tunable White LED Fixtures.

In addition, we have developed different Tunable White Light Fixtures (e.g., dimmable white LED track lights) to support customers' needs. These solutions can introduce dynamic lighting to new applications so that different customers can feel the simple dimming and color mixing solutions for a whole unique lighting experience.

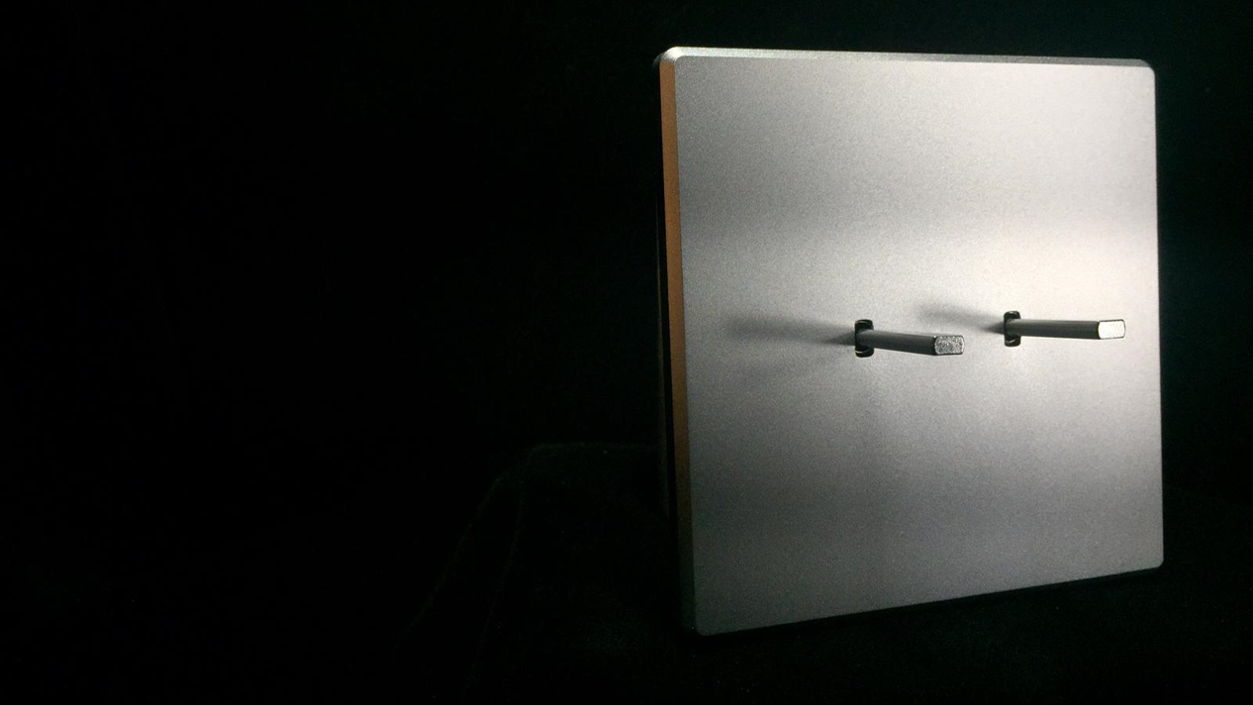

(Right) The two white rotary knobs on the solid aluminum alloy faceplate are our DZ3G450DIAL and DZ1G1TEN for brightness and color temperature control. They connect to the DZ1G300TUNE (not shown at the back of the demo); the Tunable White Controller further powers the 15W Tunable White Light Bar (LTML-6527-X15-3X1-15D_BK).

These are commonly known as "dimmer switches" in the market. Phase-cut dimming is a generic term that describes the dimming operations by controlling the input power from the Live wire to the lights. Based on the different phase-cut methodologies, we can further divide phase-cut dimming into

These are commonly known as "dimmer switches" in the market. Phase-cut dimming is a generic term that describes the dimming operations by controlling the input power from the Live wire to the lights. Based on the different phase-cut methodologies, we can further divide phase-cut dimming into  1-10V and 0-10V, which are often confused in the market, both refer to controlling the output of the LED driver linearly to dim the light. The most significant difference is how the LED driver changes its output with an input below 1V.

1-10V and 0-10V, which are often confused in the market, both refer to controlling the output of the LED driver linearly to dim the light. The most significant difference is how the LED driver changes its output with an input below 1V. Dynamic lighting, sometimes known as

Dynamic lighting, sometimes known as